Digital Manufacturing

Designed for You

Neway is one stop supplier for silicone rubber, plastic & metal products. We have complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing & inspection to export.

Having one supplier like Neway for the complete assembly will allow for better design, quality, and fit of all the individual parts.

Injection Molding

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould. Uses a ram or screw-type plunger to force molten plastic or silicone rubber material into a mould cavity

Rubber Compression Molding

Compression molding is a forming process in which a rubber material is placed directly into a heated metal mold then is softened by the heat and therefore forced to conform to the shape of the mold, as the mould closes.

LSR injection molding

Liquid Silicone Rubber (LSR) is high-purity platinum cured silicone. LSR's physical, chemical and thermal properties make it highly suitable for products where performance, durability and high quality are a necessity.

Mould Making

Molds are created in different ways to do different jobs. Neway uses tool steel to create our molds. These steel molds can last for millions of cycles and come with a lifetime warranty.

3D Printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Plastic Extrusion Molding

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section.

Rubber Extrusion Molding

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section.

CNC Machining

CNC Machining processes a piece of material to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation.

Die Cutting

Die cutting refers to a process in which you use a machine to mass-produce cut-out shapes. It saves time and makes your cut-out shapes look professional and consistent every time.

Professional Manefacturers

of Custom Plastic Parts

One-stop supplier for plastic, silicone rubber and metal components, with advanced equipment and a variety of production technology, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Neway, our ISO9001-certified facilities are designed for both rapid prototyping, low-volume production and mass production of end-use components.

How to control quality?

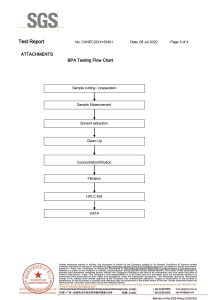

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on.

For pre-production samples, we'll provide several pieces to our clients for assembly and function testing. We will seal the samples in time once they're approval.

For Bulk Production, we'll do the IPQCS & PQC (Multiple Sampling Inspection) during production and we'll do the FQC (Sampling Inspection) after deburr or breaking sharp edges. In order to timely find problems, solve problems, reduce defective products, and reduce manufacturing costs.

After packing and assembling, we'll do the OQC (Sampling Inspection) to make sure the final goods are qualified.

Work with Neway, your business is in safe and your money is in safe!

Technical supports

Design For Manufacturability (DFM) report, it's a bridge between product developer and mold manufacturer. It has been implemented in many manufacturing industries and proved to a sufficient way to improve efficiency.

A comprehensive DFM report for mold making project would be the first step to success. As a mold maker,the more potential problems you foresee, the less risks you had in the manufacturing process. Let’s make the design perfect at beginning.

If you don't have 3D drawings and only have design idea or samples, we can help you create the 3D drawings.

If you can dream it, we can build it!

How to work with us & Our ordering Process

Receive your inquiry

Upload a 3D CAD file in .stp, .igs, .prt format, with detailed requirements to get a quote.

Manufacturing Analysis

Once order / price confirmed, we'll send you Design for Manufacturability (DFM) analysis within 1~2 working days.

Production

We will purchase the raw materials and arrange production once received your approval on the DFM report.

Quality Control

We seriously take care of the quality control from IQC to OQC, throughout each step of the production and all documents are tractable.

Delivery

We will send you the Packing List with pictures to arrange the shipment.

The complete workflow is shown below

Once the order is confirmed, our engineer will provide the DFM report (Design for Manufacturability Analysis) to customer for approval. We’ll start to design the mould drawing and mould making after the DFM report approved by customer. Once the mould making is finished, we’ll make several pieces of pre-production samples for test, if the dimensions are correct, then we will send the samples to customers for final confirmation. …

Some of the applications we've produced for

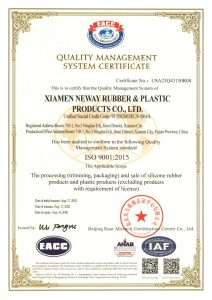

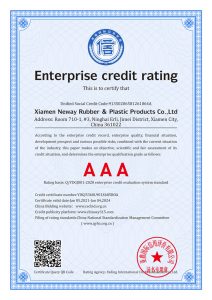

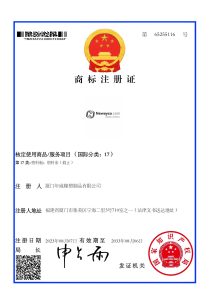

Certificates

NEWAY has obtained ISO 9001:2015 certificates, and FDA, BPA Free, UL94 V0 certificates, dedicated to strict quality control and thoughtful customer service.Quality is the domain of our special focus. All parts of our production are subject to a strict control at each phase of the production.

COOPERATIVE BRAND

Cooperate with many well-known companies